Our services

SINGLE COMPONENTS BECOME

PART OF A WHOLE

As a medium-sized turned parts manufacturer, we are constantly working on process optimization and the modernization of our machinery. Our standards are technical progress and acting in the interests of our customers. Quality and reliability are the measure of all things for us. Precision - Made in Germany.

From bar

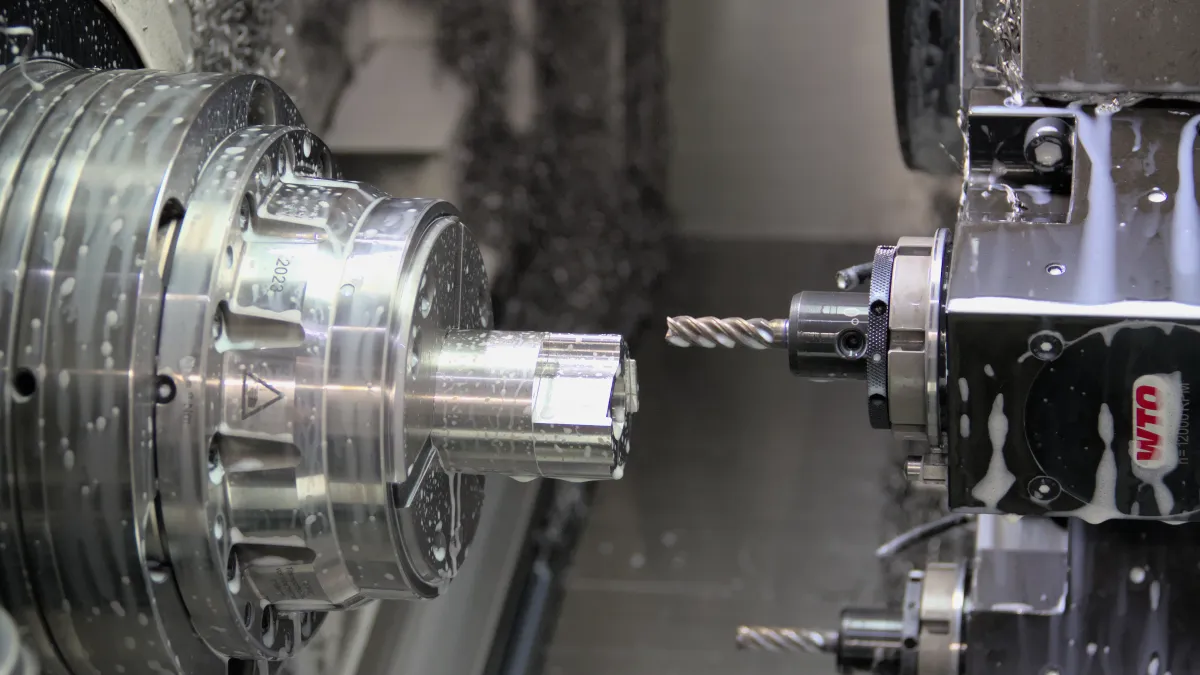

Whether small series of 500 pieces or series production of 100,000 pieces, we manufacture your turned parts in diameters from 3 to 80 mm. We machine almost all machinable metals such as free-cutting steels, case-hardening steels, stainless steel V2A and V4A, brass and various aluminum alloys.

We use CNC lathes from renowned manufacturers such as CITIZEN and DMG MORI for this purpose.

In the chuck - contract and contract manufacturing

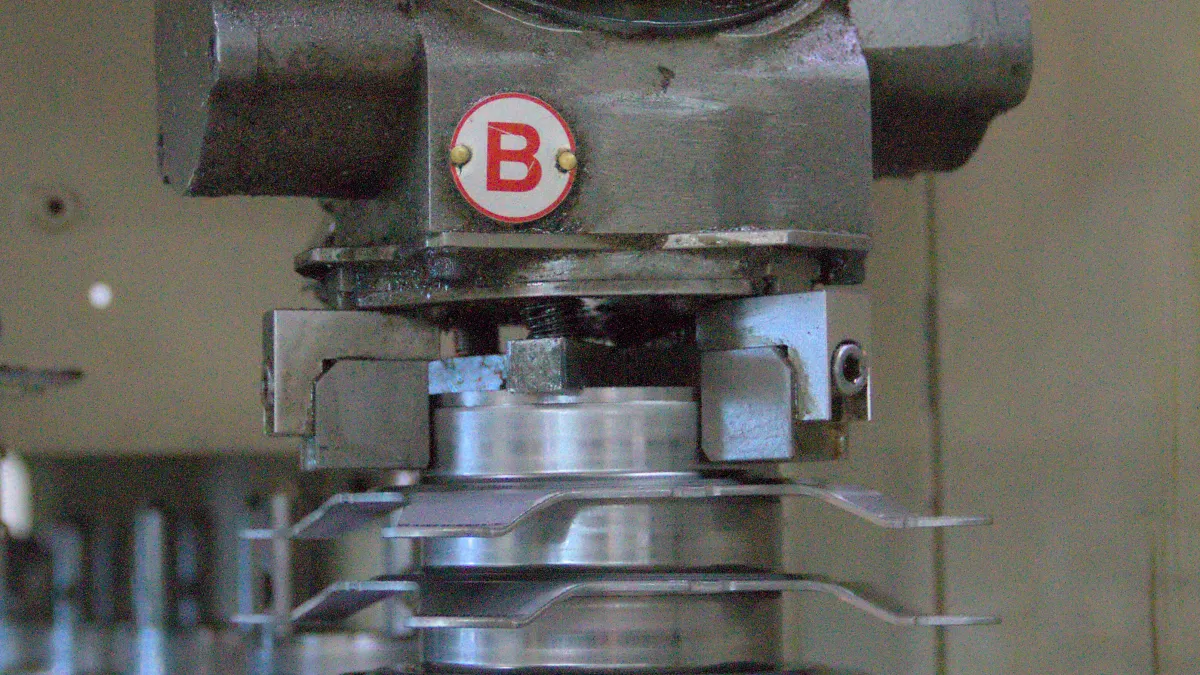

In addition to our core competence of turning from bar stock, we also machine cast and deep-drawn parts up to a diameter of 150 mm. Our EMCO, TAKAMAZ and MURATEC machines can be used to efficiently rework small to medium-sized series.

Finish & subsequent processing

With the help of our long-standing partners, we can also provide you with finishes such as electroplated zinc coatings, electroless and electroplated nickel, anodizing and various heat treatments.

Our services at a glance

From bar

DIMENSION RANGE:

ø2mm to ø80mm

TYPICAL LOTS:

from 500 to >100.000 pieces

TYPICAL MATERIALS:

V2A, V4A, aluminum, steel,

brass, aluminum bronze, copper

IN THE FOOD I ORDER-

& CUSTOM PRODUCTION

PROCESSING OF

INSERT PARTS

up to approx. ø150mm

TYPICAL LOTS:

100 to >25,000 pieces

FINISH &

FINISHING

Electroplating

Technical and optical anodizing

Pickling and electropolishing

Thermal deburring

Heat treatment

Bronzing, joining

Riveting, assembly